Top Structural Engineering Design and Detailing Services for Manufacturing Plant Projects

Beneath the relentless rhythm of machinery and the expanse of assembly lines, structural engineering stands as the silent force that keeps manufacturing operations running smoothly. The right structural engineering partner is the difference between seamless project execution and costly delays that can disrupt production and erode your bottom line. Choosing an experienced structural engineering team ensures that your facility’s infrastructure is not only robust, but also adaptable to the ever-evolving demands of modern manufacturing.

From optimizing load-bearing systems to integrating efficient layouts for both people and equipment, a skilled partner anticipates potential issues before they arise. This foresight reduces downtime and minimizes unplanned repairs, directly translating into higher productivity and profitability.

Collaboration with knowledgeable engineers streamlines compliance with safety codes and industry standards—essential for safeguarding your workforce and avoiding regulatory setbacks. In today’s competitive landscape, prioritizing structural integrity through expert guidance isn’t just a wise decision; it’s an investment in the long-term success of your manufacturing operations.

Why Specialized Structural Engineering is Essential for Manufacturing Plant Construction

Manufacturing plants are anything but ordinary. These dynamic environments are defined by heavy equipment, constant vibration, and uncompromising safety standards. Only specialized structural engineering firms possess the expertise to tackle these unique demands. Structural and civil engineers collaborate to design robust foundations capable of supporting massive weights, leveraging advanced modeling software to anticipate and address every detail. In such a high-stakes setting, even a minor flaw in structural design can result in operational downtime and millions in lost productivity.

This is why investing in experienced engineering partners is not just prudent—it’s essential. Their deep understanding of industrial requirements ensures that every aspect, from load distribution to seismic resilience, is meticulously evaluated and addressed. Cutting-edge solutions like vibration isolation systems and reinforced concrete slabs are tailored specifically to accommodate the relentless forces at play within these facilities.

By prioritizing expert structural design, manufacturing plants can operate with confidence, knowing their infrastructure will withstand both daily stresses and unforeseen challenges. Ultimately, this proactive approach safeguards productivity, protects workers’ safety, and preserves the long-term value of critical assets.

The Role of Structural Engineers in Manufacturing Plant Projects

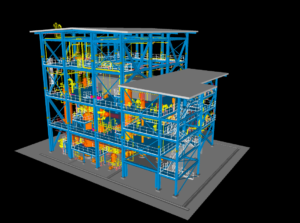

Structural engineers are tasked with creating building systems that not only guarantee safety but also maximize efficiency and control construction costs. Their expertise is crucial for analyzing complex load scenarios and designing structures that withstand both operational stresses and environmental forces. By partnering with civil engineers, they integrate advanced software and digital design services—including BIM—to deliver models that meet rigorous safety standards while minimizing environmental impact. Moreover, structural engineers play a pivotal role in fostering innovation within the construction industry.

Through the adoption of sustainable materials and cutting-edge construction techniques, they help reduce resource consumption and waste. Their careful attention to detail ensures that every aspect of a structure—from its foundations to its superstructure—is optimized for durability and long-term performance.

Collaboration with other professionals, such as architects and environmental consultants, enables structural engineers to address challenges proactively during the design phase. This interdisciplinary approach not only streamlines project delivery but also results in resilient buildings that adapt well to changing climate conditions. Ultimately, by prioritizing both safety and sustainability, structural engineers are instrumental in shaping the built environment for future generations. Their commitment to quality design practices leads to buildings that are not only functional but also environmentally responsible and economically viable.

Innovative Solutions for Complex Projects

Every manufacturing plant presents unique challenges. Leading structural engineering firms respond with innovative, sustainable solutions that optimize project management and facilitate smooth construction processes. Integrating structural design with BIM services creates a coordinated digital model, streamlining project management through accurate shop drawings and enhanced collaboration among all stakeholders.

This collaborative digital environment not only reduces costly errors and rework but also accelerates decision-making by providing real-time access to up-to-date project information. By leveraging BIM, structural engineers can foresee potential clashes early in the design phase, allowing for proactive problem-solving that saves both time and resources.

The integration of sustainable practices within these models ensures that projects are environmentally responsible from inception to completion. As a result, clients benefit from reduced operational costs, improved building performance, and greater long-term value—demonstrating why embracing advanced structural engineering solutions is essential for modern manufacturing facilities.

Comprehensive Detailing Services: Steel, Precast, and Rebar

Top structural engineering companies are renowned for their steel detailing expertise. Their services encompass:

– Steel Detailing: Precise modeling and drafting ensure every beam, column, and connection is fabricated and installed flawlessly, improving efficiency and safety.

– Precast Detailing: Accurate detailing of precast elements guarantees consistency, reduces on-site labor, and accelerates construction timelines.

– Rebar Detailing: Detailed reinforcement layouts are essential for structural integrity, especially in heavy-duty industrial environments.

By delivering comprehensive design and detailing services, these firms reduce construction costs, minimize errors, and expedite on-site construction, ensuring your manufacturing plant is operational on schedule.

The Value of Detailed Shop Drawings

Detailed shop drawings are the backbone of safe and efficient plant construction. They specify every aspect of steel, precast, and rebar detailing, giving fabricators and contractors the clarity they need to execute with confidence. This level of precision translates to fewer change orders, reduced waste, and a safer job site.

Partner with a Proven Structural Engineering Firm

For manufacturing plant projects, there’s no substitute for experience and expertise. Choose a structural engineering partner known for their dedication to accuracy, innovation, and seamless project delivery. With the right team by your side, you’ll ensure your facility is built to support your operations today—and well into the future.